Morrow’s engineering and research team have successfully increased the cycle life of the company’s first product by 30%. Simultaneously, the energy density has increased by 10%.

Morrow can now deliver a commercially viable, thoroughly tested, competitive LFP product.

“The increased performance of the LFP batteries has been achieved in a very short period. It comes from optimised battery design, an improved organisational skill set, and a leaner and enhanced production process in our quest for operational excellence,” says Bacher.

Since November last year, the company has shipped LFP samples to several potential customers for testing and validation. The company has adjusted and improved the cell chemistry composition, battery cell design structure, and production process.

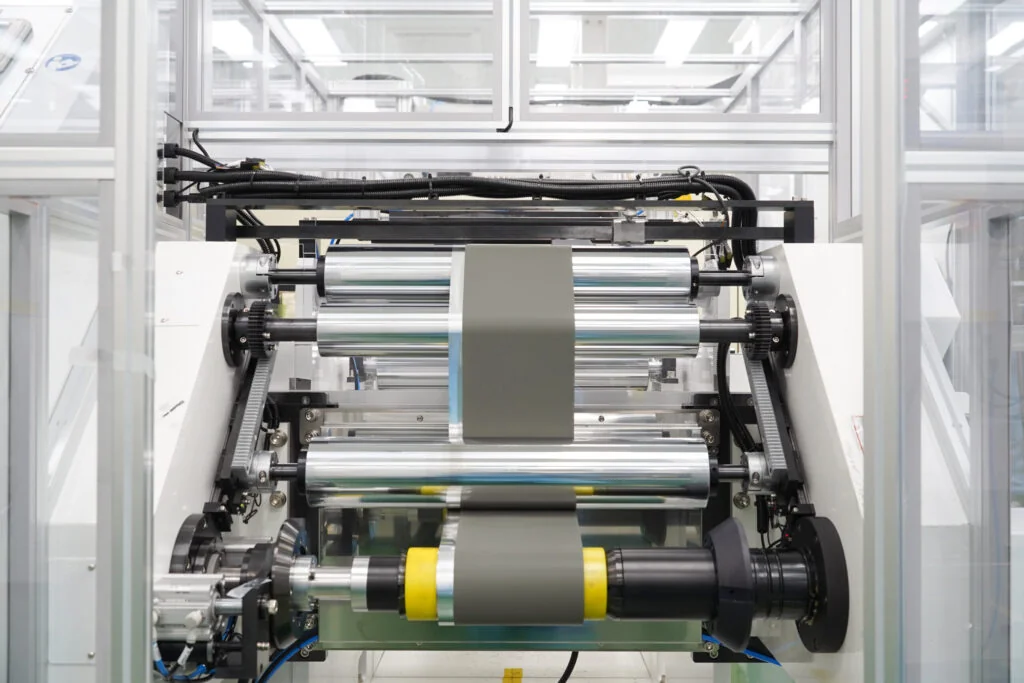

Morrow will begin production from its first gigafactory in Arendal, Norway, in the second half of 2024 and start mass production in the fourth quarter.

The company will initially produce LFP batteries based on a known and tested production process, serving the markets of Battery Energy Storage Systems (BESS) and heavy-duty electric commercial vehicles, such as construction machinery. These are well-known markets where the demand forecast exceeds current supply projects by a substantial margin, resulting in a market opportunity for Morrow.

The CQL will shortly be in transit from South Korea to Norway and operational in Arendal during the second half of this year.